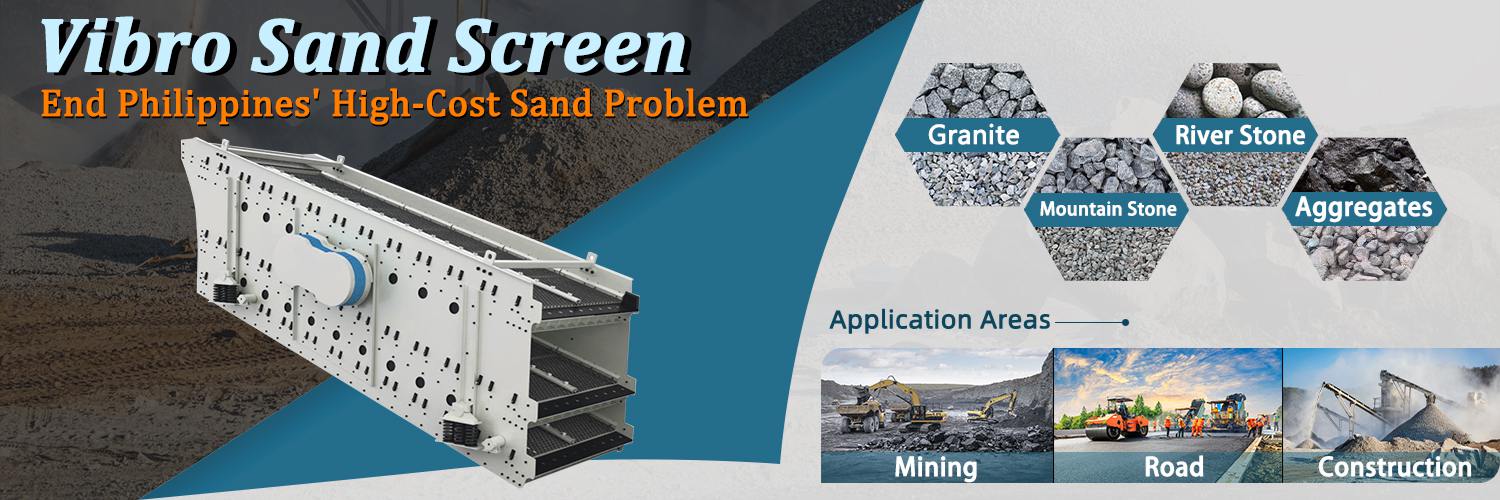

Our vibrating screen has efficient screening performance, can accurately screen ore, improve screening efficiency, and ensure the stability of product quality.

The Philippine construction industry is experiencing unprecedented growth, but the sand supply crisis is becoming increasingly severe. Traditional sand sources are not only expensive but also of unstable quality, directly affecting concrete strength and project quality. Construction companies in major cities such as Manila, Cebu, and Davao face the dilemma of sand transportation costs accounting for 30-40% of total material costs.

Efficient manufactured sand production system designed for the Philippine market, transforming local aggregates into high-quality construction sand that meets PNS standards, reducing costs by 40-60%

Mobile Vibro Sand Plant

Stationary Vibro Sand Plant

| Model | 3YK1545 | 4YK1545 | 3YK1548 | 4YK1548 | 3YK1848 | 4YK1848 |

| Sieve layer | 3 | 4 | 3 | 4 | 3 | 4 |

| Sieve area (㎡) | 20.25 | 27 | 21.6 | 28.8 | 25.92 | 34.56 |

| Mesh size (mm) | 5-50 | 5-50 | 5-50 | 5-50 | 5-80 | 5-80 |

| Max. feeding size (mm) | 400 | 400 | 400 | 400 | 400 | 400 |

| Processing capacity (m³/h) | 22-150 | 22-155 | 22.5-162 | 22.5-162 | 32-276 | 32-285 |

| Motor power (kw) | 15 | 18.5 | 15 | 18.5 | 18.5 | 22 |

| Sieve specification (mm) | 1500×4500 | 1500×4500 | 1500×4800 | 1500×4800 | 1800×4800 | 1800×4800 |

| Total weight (kg) | 6800 | 7800 | 7700 | 8700 | 9600 | 11100 |

| Dimensions (L×W×H) (mm) | 5360×2210×1610 | 5930×2210×2060 | 5660×2210×1610 | 6230×2210×2060 | 5660×2550×1780 | 6290×2550×2160 |

| Model | 3YK1854 | 4YK1854 | 3YK2160 | 4YK2160 | 3YK2460 | 4YK2460 |

| Sieve layer | 3 | 4 | 3 | 4 | 3 | 4 |

| Sieve area (㎡) | 29.16 | 38.88 | 37.8 | 50.4 | 43.2 | 57.6 |

| Mesh size (mm) | 5-80 | 5-80 | 5-100 | 5-100 | 5-100 | 5-100 |

| Max. feeding size (mm) | 400 | 400 | 400 | 400 | 400 | 400 |

| Processing capacity (m³/h) | 32-312 | 32-336 | 50-475 | 50-497 | 70-620 | 80-680 |

| Motor power (kw) | 22 | 30 | 30 | 37 | 37 | 45 |

| Sieve specification (mm) | 1800×5400 | 1800×5400 | 2100×2600 | 2100×2600 | 2400×6000 | 2400×6000 |

| Total weight (kg) | 10840 | 12840 | 12800 | 14800 | 17600 | 19600 |

| Dimensions (L×W×H) (mm) | 6260×2550×1780 | 6830×2550×2160 | 7030×2840×1910 | 7300×2840×2380 | 7300×3140×1910 | 7600×3140×2380 |

Our Vibro Sand Plant uses advanced vibration screening technology and washing systems to transform locally available aggregates into high-quality manufactured sand with excellent grading. The system includes multi-stage screening, efficient cleaning, and water recycling modules, ensuring that the produced sand has optimal particle shape and controlled fine content, fully meeting concrete production requirements.

Compared to traditional sand-making equipment, our Vibro Sand Plant has outstanding advantages such as low energy consumption, simple maintenance, and strong adaptability, making it particularly suitable for the power conditions and raw material characteristics across the Philippines. The equipment adopts a modular design that can be flexibly configured according to production needs, perfectly handling different scales from 45 to 2100 tons per hour.

Vibro Sand isn't produced directly by a single crusher (such as a roller crusher or VSI sand making machine). Its production involves a continuous process:

Large rocks are first crushed into smaller aggregates (such as G1, G2, and 3/4") using a jaw crusher or cone crusher.

01

These smaller aggregates are then fed into a sand making machine (such as a roller crusher or VSI impact crusher) for further crushing into sand.

02

The resulting mixture (containing sand and stone dust of varying sizes) is fed to a vibrating screen.

03

The vibrating screen precisely classifies the material through multiple screens. The finest, most uniform sand that passes through the finest screen (usually 0-2mm or 0-3mm) is called Vibro Sand.

04

Tips: If your raw materials have low mud content, we recommend equipping the vibrating screen with a spray system. If the mud content is very high, we recommend equipping it with a sand washer.

SMAT Vibro Sand Plant in the Philippines:

SMAT provide various concrete and crushing machine for your project in the Philippines