The SMAT double roller crusher is an innovative solution to the high cost of sand and gravel in the Philippines. More economical than a VSI sand maker, it can process local high-mud stone, river rock, mountain rock, and aggregates, producing high-quality construction sand at a 40-50% cost reduction.

The SMAT double roller crusher is an innovative solution to the high cost of sand and gravel in the Philippines. More economical than a VSI sand maker, it can process local high-mud stone, river rock, mountain rock, and aggregates, producing high-quality construction sand at a 40-50% cost reduction.

Double Roller Crusher

Productivity: 2-220t/h

Roller Diameter: 400-1800mm

Roller Length: 250-1000mm

Hydraulic Double Roller Crusher

Productivity: 8-390t/h

Roller Diameter: 1000-2000mm

Roller Length: 800-12000mm

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roller Diameter(mm) | φ400 | φ600 | φ700 | φ800 | φ1000 | Φ1200 | Φ1500 |

| Roller width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Feed size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharge Opening(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Processing capacity(t/h) | 3-10 | 5-20 | 10-30 | 15-40 | 20-50 | 25-70 | 30-110 |

| Power Model | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor Power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

Construction industry faces rising sand and aggregate prices, impacting infrastructure and real estate development

Does your project face these challenges? Natural sand mining is limited, and supply is unstable. Imported sand is expensive, increasing construction costs by 30% or more. Traditional sand-making equipment consumes a lot of energy and has high maintenance costs. Vertical shaft impact crushers have strict material requirements and are not suitable for local conditions. Unstable power supply in remote areas affects equipment operation.

01

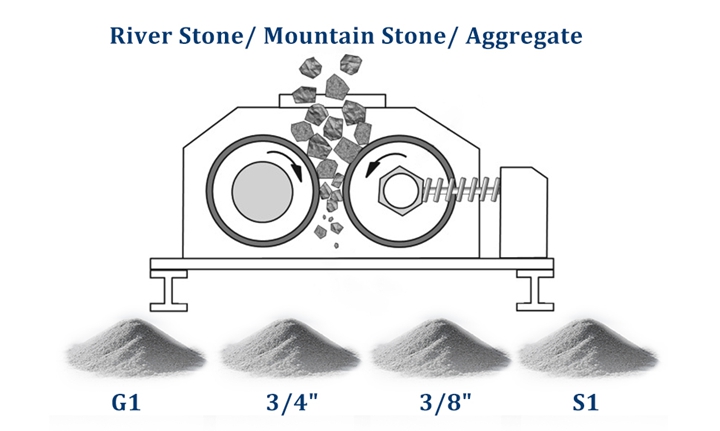

Due to the unique topography of the Philippines, we considered using a double roller crusher instead of a sand making machine to more efficiently process local raw materials containing a certain amount of moisture and clay. This machine can produce high-quality sand that meets Philippine construction standards, such as G1, 3/4", 3/8", S1. Adapts to high moisture content and clay-rich materials.

02

1. Its compact structure, light weight, and small size can reduce space costs and are easy to operate and maintain.

2. The new equipment uses multiple protection devices and interlocking devices such as mechanical, electrical, and hydraulic devices to effectively protect the motor, crusher, and the entire system. It does not need to replace the roller body of the mill for life, while the old double roller mill needs to be disassembled for overhaul and the roller body needs to be replaced after one year of use.

3. Compared with other types of crushers, it has no requirements for the moisture content of the crushed material and is non-sticky and non-blocking.

4. Equipped with a hydraulic automatic retreat device, it can effectively prevent the feed object from damaging the tooth roller. It is also equipped with an intelligent cleaning device, which can automatically remove the adhered materials on the crusher cavity wall at working intervals.

5. Suitable for a variety of materials. It can crush brittle materials with medium and low hardness, such as bituminous coal, anthracite, lignite and coal gangue, and can also be used for sintered ore, coke, slag, shale and limestone.

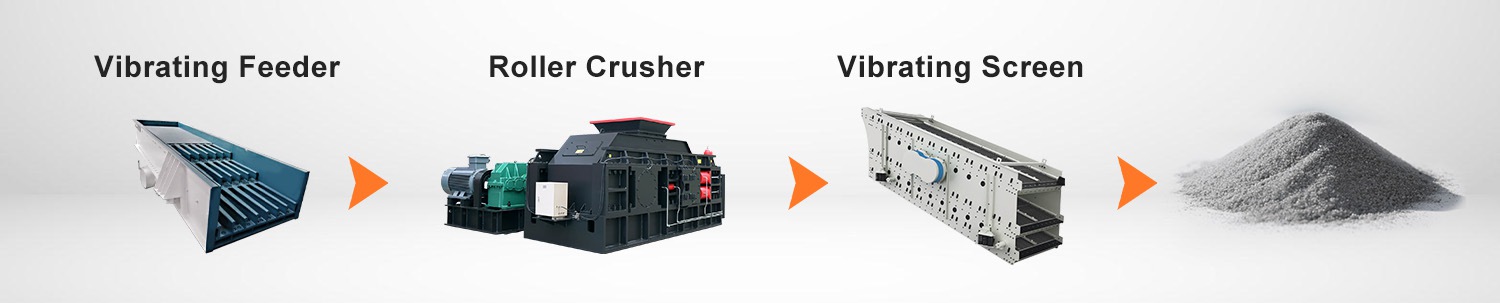

The SMAT Vibro Sand Plant has been tested by the Philippine market. By optimizing the screening process, we help customers quickly process large quantities of stones in mines, rivers and other places, thereby improving production efficiency.

03

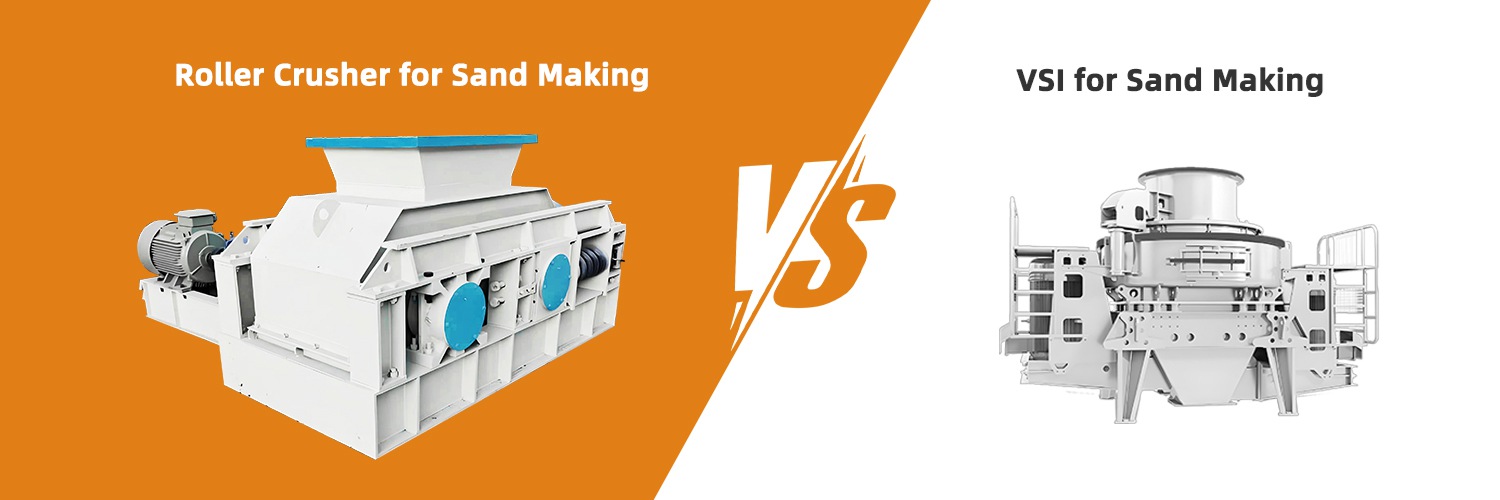

| Category | Roller Crusher | VSI Crusher |

| Particle Shape | Flakiness more | Few flakiness, mainly cubical |

| Fineness Reference | 2-4.5 mm Coarse Sand | 2.3-5.0 mm Medium Sand |

| Capital Cost | Low (low initial equipment investment and low maintenance cost of wearing parts) | High (high equipment investment and high maintenance cost) |

| Wear Parts | Grinding roller. Long service life and low replacement frequency | Rotor and hammer. Frequent replacement |

| Maintenance Complexity | Low(only need to adjust the gap between the rollers, the discharge can be less than 5mm. Only need to adjust the roller gap regularly) | High (must be equipped with vibrating screen adjustment, high sand return, rotor dynamic balance calibration, operating experience required)) |

| Feed Material | Medium hard rock (limestone, etc.) | High hard rock (granite, etc.) |

| Suitable sand type | Ordinary concrete sand | High-strength concrete/Asphalt sand |

SMAT factory provides a variety of sand making solutions, these are the four most popular ones.

If your raw materials are of medium and low hardness, then we recommend this solution.

If your raw materials are of high hardness, you can also consider this solution.

If you pursue low cost and do not have high requirements for finished sand, we also recommend you to use this solution.

At the same time, we can also provide solutions for rod mills to make sand.

If you have more solution requirements, please contact us, and we will discuss the most suitable customized solution for you.

SMAT Mobile Crushing Plant in the Philippines

SMAT provide various concrete and crushing machine for your project.