SMAT manufactures different type mobile crushing stations for river stone & mountain stone to get perfect S1, 3/8, 3/4, G1 products. SMAT has portable crushing line with capacity 1-20 tph and big capacity mobile station with capacity 20-500 tph.

Welcome to visit our office in Quezon or warehouses in Bulacan, Davao, Cebu, Bacolod etc.

Filipino engineers team can help the installation, commissioning and maintenance.

Tired of the high costs and logistics nightmares of transporting raw materials across islands? SMAT Mobile Crushing Plant is your game-changing solution. Designed specifically for the scattered islands, complex job sites, and fast-paced projects of the Philippines, our track-mounted crushers eliminate the need for fixed foundations. Move directly to your material source—be it a remote mine in Mindanao or a tight urban demolition site in Manila—and start producing valuable aggregates within hours, not weeks. Turn distance and difficult terrain into your competitive advantage, and watch your transport costs plummet while your profits soar.

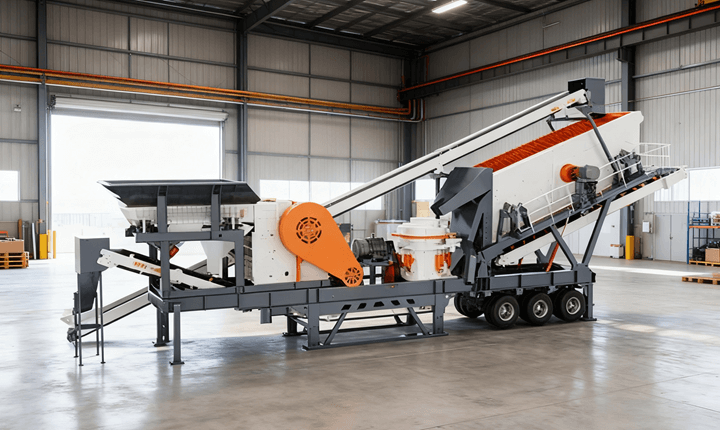

4 in 1 Mobile Crushing Plant

Feeder+Jaw Crusher+Cone Crusher+Screen

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

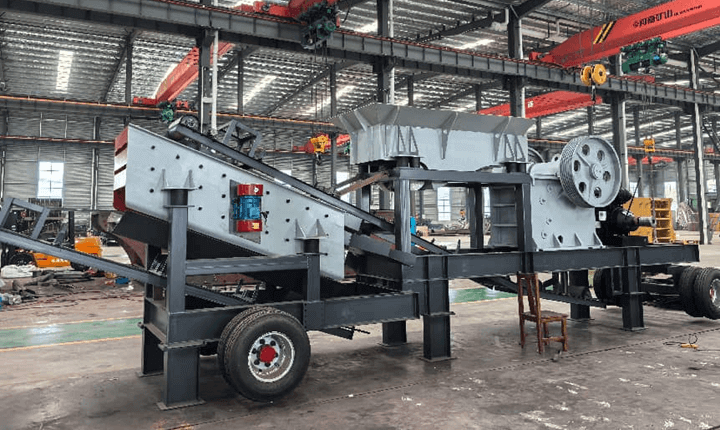

Portable Crushing Plant

Feeder+Jaw Crusher+Impact Crusher+Screen

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

4 in 1 Mobile Crushing Plant

Feeder+Jaw Crusher+Fine Jaw Crusher+Screen

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Mobile Sand Crushing Plant

Feeder+Sand Crusher+Screen

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

From versatile all-in-one plants to specialized sand makers, we have a configuration to maximize your output. Below are our most popular solutions for the Philippine market. Unsure which one fits your material? Contact our local experts for a free consultation.

Best suited for: River Stone, mountain stone etc.

Crushing stages: primary (jaw) + secondary (cone) for finer output

Discharge particle size: S1, 3/8, 3/4, G1

The best solution for the beginner——small capacity jaw crusher and vibrating screen

Best suited for: Mountain stone & rive stone

Discharge particle size: S1, 3/8, 3/4, G1

Applicable to: high-precision crushing (quarry, mineral processing)

Crushing level: primary crushing (jaw) + fine crushing (secondary jaw), uniform particle size

Discharge particle size: 0-20 mm (suitable for sand and fine aggregate)

Best suited for: hardness materials (granite, basalt)

Discharge particle size: 0-5 mm (High-quality manufactured sand is used in concrete or dry-mixed mortar.)

Best suited for: Natural sand and manufactured sand

Capacity: 10-200 tph

Best suited for: quarries, construction sites, and river management projects across the Philippines.

Discharge particle size: Designed for the Philippine archipelago - easy relocation between islands to cut logistics costs.

Mining and Quarrying in Rugged Terrain:

Why transport raw ore on rugged roads? Deploy your SMAT mobile crushing equipment directly at the mining site. On-site primary crushing significantly reduces transportation costs and truck wear.

Construction Projects:

From national highways to new bridges across islands, our equipment moves in sync with your project schedule. Positioning equipment near each new road segment ensures timely aggregate supply, guaranteeing your schedule and budget stay on track.

Urban Recycling:

Transform construction waste and demolition debris from disposal costs into revenue streams. Process construction waste and demolition debris directly on-site into valuable recycled aggregate for new construction projects, aligning with green building trends and saving on landfill costs.

River Management and Sand Production:

With river sand mining heavily regulated, our mobile sand making equipment offers a legal and sustainable alternative. Process river pebbles or hard rock into high-quality manufactured sand, ensuring a stable supply for your construction projects.

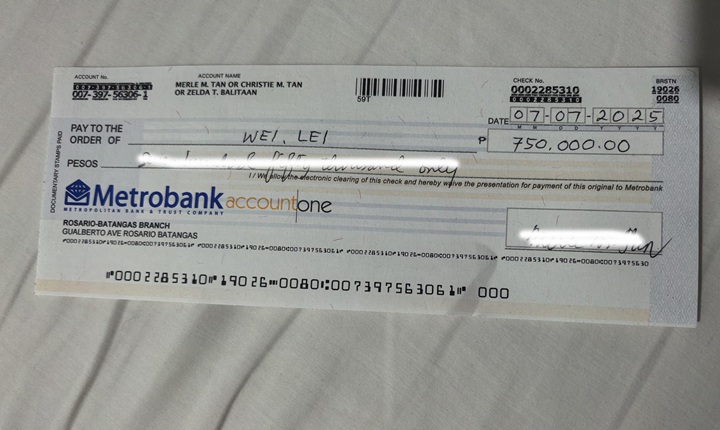

At SMAT Philippines, we ensure your investment is smooth and supported every step of the way. We go beyond just selling machinery by providing true local partnership:

We accept Peso payment and local checks, simplifying your procurement process.

01

Benefit from door-to-door delivery and a strategic network of local warehouses in Quezon, Bulacan, Bacolod, Cebu, and Davao for faster response.

02

Our Filipino engineers are not just available; they are committed to providing on-site guidance, commissioning, and training, ensuring your team operates at peak efficiency.

03

We believe in regular site visits to proactively check on equipment performance and offer operational advice, ensuring you get the maximum return on your investment.

04

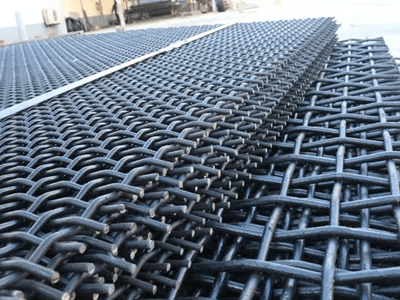

Whether you operate Stationary or Mobile equipment, consistent production relies on high-quality wear parts. SMAT maintains a local parts warehouse in the Philippines to ensure fast supply and minimize your downtime.

End-to-End Service, Mula sa Simula Hanggang Wakas: From design and professional installation to commissioning and scheduled maintenance, we offer a true worry-free, one-stop solution for your crushing machine's entire lifecycle.

SMAT Mobile Crushing Plant in the Philippines

SMAT provides various concrete machine and crushing machine for your project.