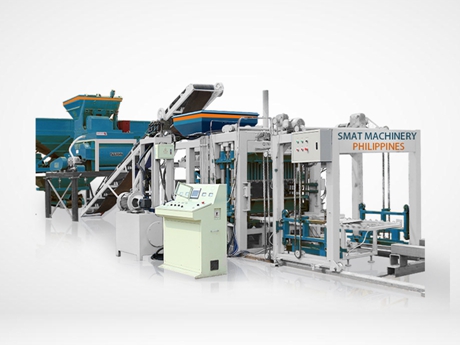

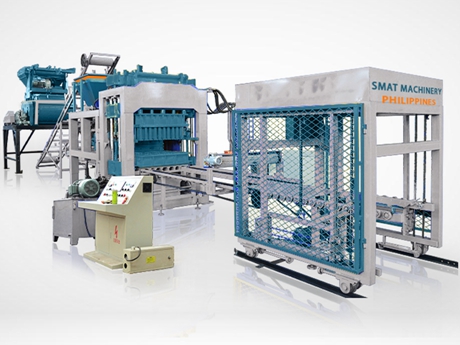

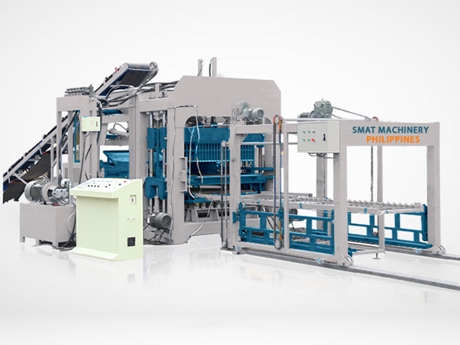

- Fully Automatic Block Machine

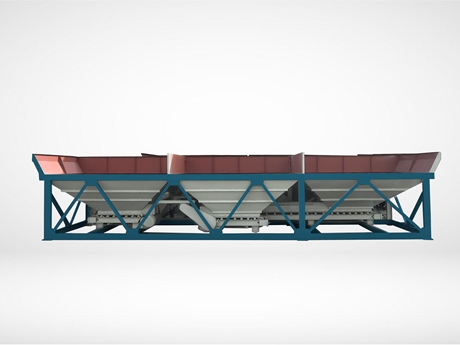

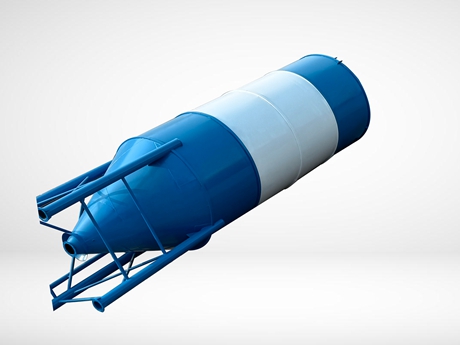

- Concrete Mixer & Supporting Equipment

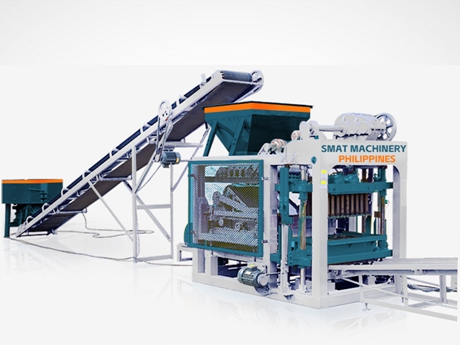

Model: QT4-25

Model:QT3-15

Model: QT4-15

Model: QT5-15

Model: QT6-15

Model: QT8-15

Model: QT10-15

Description

Built for Philippine Construction: Your High-ROI Block Production Solution

The Philippine construction boom demands reliable and economical building materials. SMAT block machines put you in control, transforming local sand and gravel into high-quality blocks. Since establishing our roots in the Philippines in 2018, we have helped numerous clients build successful block manufacturing businesses—whether for their own projects or to supply the growing local market.

Hot Sale

QT4-24

The QT4-24 exemplifies steady and economical performance. Its 24-second molding cycle (producing 4 blocks per cycle) offers a stable and reliable production pace. It allows you to obtain high-quality blocks while benefiting from a more favorable initial investment, making it a smart choice for risk management and a steady start.

- Cost-Effective: Offers a highly competitive entry price, significantly lowering the investment threshold and financial pressure.

- Durable & Reliable: Robust construction ensures stable operation and easy maintenance, designed for long-term, consistent production.

- Energy Efficient: Optimized power configuration delivers reliable performance while helping to reduce your long-term electricity costs.

QT4-15

The QT4-15 sets the standard for efficiency. With a fast 15-second molding cycle producing 4 standard blocks each time, it's engineered for customers who need rapid production and high-volume delivery. It ensures your output keeps pace with market demands, whether fulfilling large unexpected orders or supplying fast-moving construction projects.

- High Output & Efficiency: Shorter cycles translate to higher daily production, helping you seize market opportunities and accelerate ROI.

- Powerful & Stable: Equipped with a high-quality vibration system to ensure every block is solid and consistent, even at high speed.

- Smart & User-Friendly: Automated controls for simple operation, enabling quick worker training and reducing reliance on highly skilled labor.

Specification

| Model | QT4-24 | QT3-15 | QT4-15 | QT5-15 | QT6-15 | QT8-15 | QT10-15 |

| Molding Cycle | 24 | 15 | 15s | 15s | 15s | 15s | 15s |

| Vibration Frequency | 3500r/min | 4500r/min | 4600r/min | 2800-4500r/min | 4500-5100r/min | 2800-4500r/min | 2800-4500r/min |

| Exciting Power | 50kn | 50kn | 55kn | 60kn | 65kn | 85kn | 110kn |

| Overall Power | 20.6kw | 20.75kw | 27.5KW | 32kw | 28.75kw | 51kw | 67KW |

| Pallet Size | 850x550mm | 680x550mm | 1020x570mm | 1100x550mm | 850x680mm | 950x900mm | 950x900mm |

| Overall Dimension | 5600x2240x2400mm | 5990x4260x2620mm | 7310*2500*2810mm | 7310x26000x2890mm | 7450x24500x3050mm | 8300x28000x2900mm | 9350*3000*2900mm |

Related Cases

Traditional Brick Factory Capacity Upgrade Project

Project Location: Bacolod

SMAT Fully Automatic Hollow Brick Machine: Served as the core of the production line for efficiently manufacturing standard construction hollow bricks.

Client Feedback: "SMAT's automated production line has completely transformed our operation. Our output has more than doubled, and the brick quality is more uniform and durable, greatly enhancing our competitiveness in the local market."

Eco-Friendly Block Production Project

Project Location: Manila

SMAT Fully Automated Block Molding Machine: Used for producing building bricks and curbs.

Client Feedback: “SMAT’s equipment is not only stable and efficient, but it also perfectly matches the technical requirements of our eco-brick production. Their professional support enabled us to quickly establish ourselves in the green building materials sector and become the designated supplier for several government projects.”

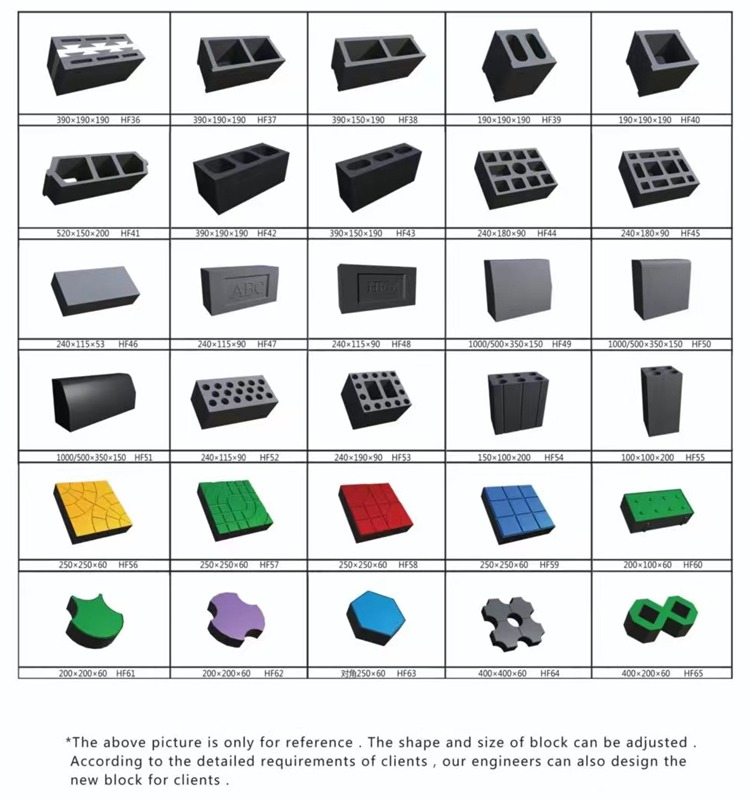

Municipal & Landscaping Projects:

Produce colored paving stones, curbstones, and grass blocks for plazas, parks, and communities.

Commercial Buildings & Perimeter Walls:

Produce standard hollow and solid blocks for shops, factories, and residential walls.

Flood Control & Slope Protection:

Produce specialized slope protection blocks for riverbanks and dikes, meeting typhoon-season challenges.

Advantage

Why SMAT is Your Reliable Choice in the Philippines?

Deep understanding of the local market since 2018. Machines are adapted to local raw materials (sand, gravel) and climate.

Local Manila Office & Filipino Engineers:

Staffed by a dedicated team of licensed Filipino engineers and technicians, we bridge the gap between you and your machine. They don't just speak your language; they understand your local working conditions, common material mixes, and industry challenges. From the moment your equipment arrives, our team is there: conducting professional installation supervision, fine-tuning machine settings during commissioning for optimal output with your specific materials, and providing comprehensive hands-on operator training until your crew runs the machine confidently. This end-to-end, face-to-face support ensures a smooth start-up and lasting peace of mind.

01

Peso Payments & Local Spare Parts Stock:

Pay conveniently in Philippine Pesos (PHP), eliminating currency exchange complexities and providing you with clear, predictable costing. More critically, we maintain a strategically stocked warehouse of genuine spare parts in the Greater Manila area. Common wear parts, hydraulic components, and electrical elements are readily available. This local stock translates to drastically reduced downtime—when you need a part, you get it in days, not weeks. It's our commitment to keeping your business running smoothly and profitably, minimizing costly production interruptions.

02

Intelligent Control System:

Democratize expertise with our advanced PLC-based intelligent control system. The heart of the machine is a user-friendly, color touchscreen interface that makes complex operations intuitive. With pre-set programs for different block types and clear step-by-step guidance, new operators can be trained effectively in a short time. This significantly reduces dependence on hard-to-find, highly specialized technicians, giving you greater staffing flexibility. The system also features real-time fault diagnostics, alerting operators to issues and suggesting solutions before they cause major problems, empowering your team to manage production efficiently.

03

Efficient Vibration & Energy-Saving Design:

Our engineering delivers a perfect balance between top-tier product quality and operational economy. The precisely tuned vibration system—combining optimized frequency, amplitude, and force distribution—compacts concrete mix thoroughly and uniformly in a shorter cycle time. This produces blocks with excellent density, consistent strength, and sharp, market-ready edges. Simultaneously, our integrated energy-saving design utilizes high-efficiency motors, optimized power systems, and intelligent load management. This synergy means you achieve higher compressive strength while consuming significantly less electricity per block, directly boosting your profit margin with every batch you produce.

04

Service

- Manufacturer price, price is lower based on same configurations and quality.

- Accept Peso payment and check.

- Door-to-Door delivery, save your time and effort.

- Local office in Quezon City, Manila. Make sure timely and rapid response to customer needs.

- Local Warehouses in Quezon, Bulacan, Bacolod, Cebu, Davao.

- Filipino engineers team are always available for on-site installation guidance, commissioning, and training services.

- Regular visiting to clients sites, thus can promptly correct improper operations.

You May Need

SMAT provides various concrete machines for sale in the Philippines, feel free to contact SMAT team.